Integrate SPC Tracking with all of your Quality Inspection Processes for Cost and Waste Reduction

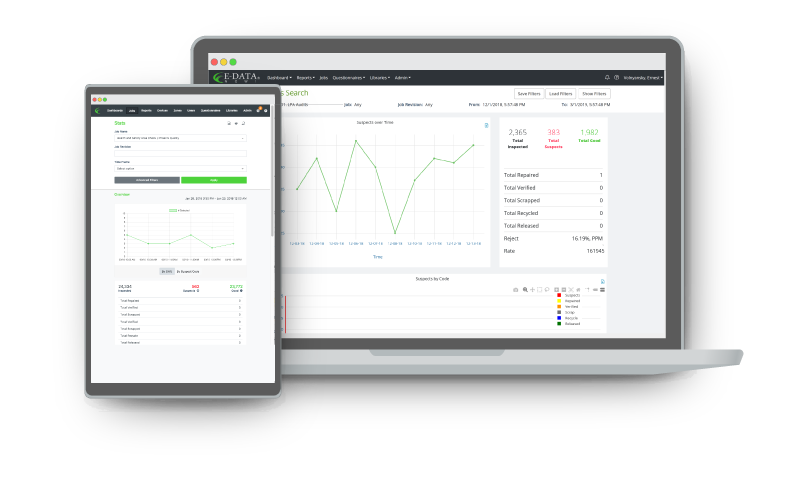

Deep dive into tolerance non-conformance data, combined with valuable process audit evidence to shift from poor quality to consistent results.

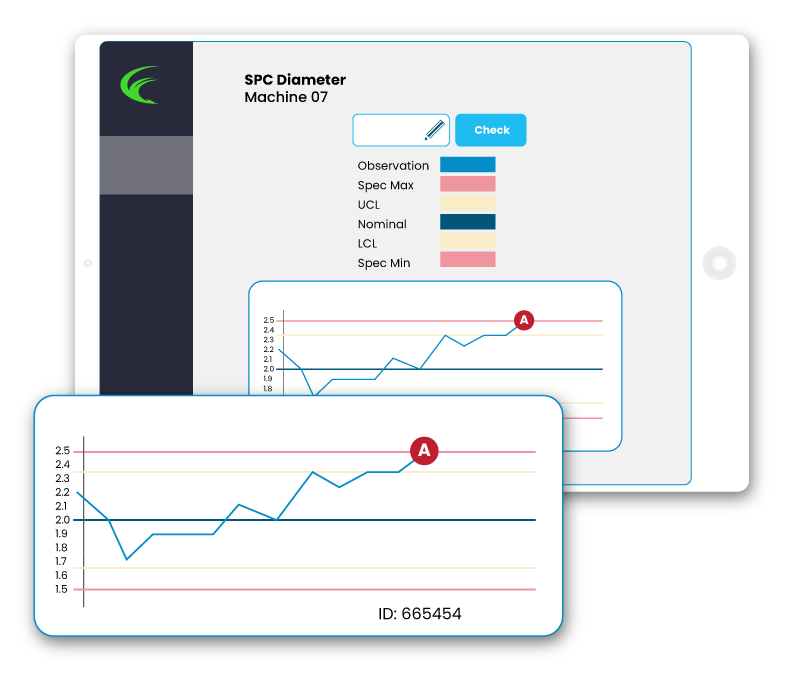

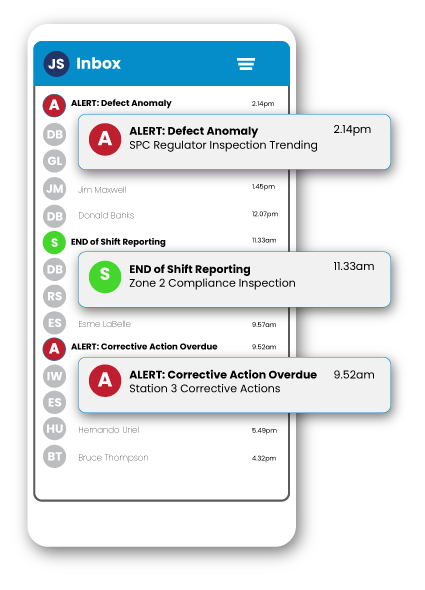

Track and react to variances in your production or processes with EDN’s built-in Real-time Statistical Process Control (SPC) recording feature. The solution for quality performance of manufacturers of all sizes. Solve the challenges associated with capturing SPC data to build reliable and repeatable action plans and processes with E-Data Now!.