Smart Devices with smart tools to audit your processes

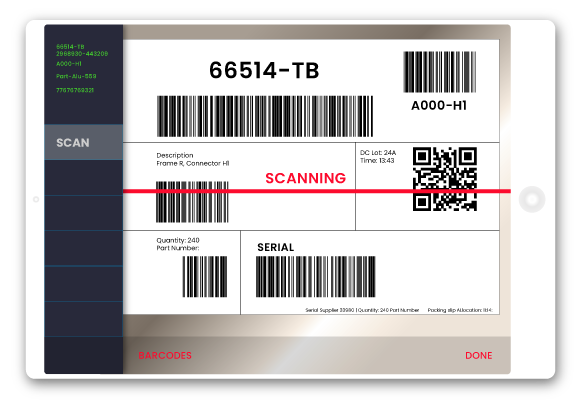

Traditionally barcodes have been used for inventory and pricing captured by dedicated scanning hardware that come with additional investment costs. Now, you can use smart devices for the same mobile flexibility but with greater capabilities of integrated audit tools.

EDN combines features to achieve a more effective understanding of processes that cause downtime, defects and waste. Recording SPC measurements, pass/fail defects, images and heat maps of regions non-conformance while scanning the barcode data, connects your areas of concern to the information contained in the barcode.

Manage your corrective actions with insight delivered to your inbox, from trends connected to specific machines, lots or suppliers.

You could be losing revenue through waste. Gain insight into part and process variance using SPC tracking software integrated with your quality audits and inspection types. Measure and control could be an asset you are missing because the paperwork has always taken too-long and results come too late.

Software with triggers for your team to react could save costs of production in many ways. Capitalize on data driven trends, stabilize loss for poor quality and grow your business through continuous improvement.